MULTI-CABINET SYSTEMS

The LEFA multi-cabinet systems are available as series systems or parallel systems depending on customer wishes. The corresponding smoking technology – liquid smoke, smoulder smoke and friction smoke – can also be freely selected and combined. Here, you can learn more about our multi-cabinet systems that can be expanded as needed, meaning that they can be adapted to increasing demands.

SERIES SYSTEMS

Product

- Smoking systems available as series systems in the aforementioned configurations

TSFR 100 1-6 with liquid smoke

TSKR 100 1-6 with friction smoke or smoulder smoke combined with liquid smoke - every system has a measuring station for chamber temperature, humidity and a core temperature sensor

- the discharge nozzles located on the side of the system, with an optional LEFA flap valve system, guarantee uniform air circulation (3 speeds possible)

- systems equipped with fully automatic cleaning function

Benefits

- fast and safe smoke production thanks to leading-edge technology

- environmentally-friendly, clean

- uniform smoke dosing and optimal air circulation control

- all multi-cabinet systems are designed to enable expansion as needed, meaning they can be adapted to increasing demands

- at request, the systems can also be delivered as a run-through technology (front and back doors)

- all connections for the media steam, water, electric, oil, gas, exhaust and fresh air save space and are easily accessible from above

- low energy and operating costs

Options

- cooling (only vaporiser, without chiller)

- cooling shower

- door with viewing window

- door opener

- active carbon filter

- Husky pump

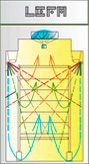

LEFA flap valve system

- with simultaneous horizontal and vertical air circulation

- this means it is easy on the products and results in the least possible loss in weight

- offers safety when it comes to a consistent, high-quality product with an attractive appearance

Microprocessor control

- 75 program memory (option with 99 programs)

- 20 increments each

- digital display for actual and target values

- easy programming of temperature, core temperature, moisture, operating time, set time

- with programming for delta cooking, core temperature and moisture deactivation

- with serial port

- “VISU-Net” software for recording measurements and process visualisation

Examples

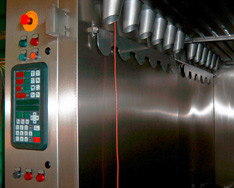

- TSFR 100 6 cabinet series system with liquid smoke – side view

- TSFR 100 4 cabinet series system with liquid smoke

- TSFR 100 6 cabinet series system with liquid smoke – front view

- TSFR 100 6 cabinet series system with liquid smoke – flap valves

- TSFR 100 6 cabinet series system with liquid smoke – interior

Accessories

H-shaped smoking trolleys

- each rack is suitable for smoking rails, cooking and collecting tray as well as baking grates.

- stainless steel smoking rails, stable triangular shape.

- stainless steel baking grate

- stainless steel collecting tray

- stainless steel cooking tray

- available for delivery with all Turbostar smoking systems.

PARALLEL SYSTEMS

Product

- Smoking systems available as parallel systems in the aforementioned configurations:ITSFR 100 2-12 with liquid smoke

ITSKR 100 2-12 with friction smoke or smoulder smoke combined with liquid smoke - every system has a measuring station for chamber temperature, humidity and a core temperature sensor

- the discharge nozzles located on the side of the system, with an optional LEFA flap valve system, guarantee uniform air circulation (3 speeds possible)

- systems equipped with fully automatic cleaning function

Benefits

- fast and safe smoke production thanks to leading-edge technology

- environmentally-friendly, clean

- uniform smoke dosing and optimal air circulation control

- all multi-cabinet systems are designed to enable expansion as needed, meaning they can be adapted to increasing demands

- at request, the systems can also be delivered as a run-through technology (front and back doors)

- all connections for the media steam, water, electric, oil, gas, exhaust and fresh air save space and are easily accessible from above

- low energy and operating costs

Options

- cooling (only vaporiser, without chiller)

- cooling shower

- door with viewing window

- door opener

- active carbon filter

- Husky pump

LEFA flap valve system

- with simultaneous horizontal and vertical air circulation

- this means it is easy on the products and results in the least possible loss in weight

- offers safety when it comes to a consistent, high-quality product with an attractive appearance

Microprocessor control

- 75 program memory (option with 99 programs)

- 20 increments each

- digital display for actual and target values

- easy programming of temperature, core temperature, moisture, operating time, set time

- with programming for delta cooking, core temperature and moisture deactivation

- with serial port

- “VISU-Net” software for recording measurements and process visualisation

Examples

- ITSKR 100 16 cabinet parallel system with liquid smoke and friction smoke – top view

- ITSKR 100 16 cabinet parallel system with liquid smoke and friction smoke – front view

- ITSKR 100 16 cabinet parallel system with liquid smoke and friction smoke – flap valve system

- ITSKR 100 16 cabinet parallel system with liquid smoke and friction smoke – processing chamber

Accessories

H-shaped smoking trolleys

- each rack is suitable for smoking rails, cooking and collecting tray as well as baking grates.

- stainless steel smoking rails, stable triangular shape.

- stainless steel baking grate

- stainless steel collecting tray

- stainless steel cooking tray

- available for delivery with all Turbostar smoking systems.